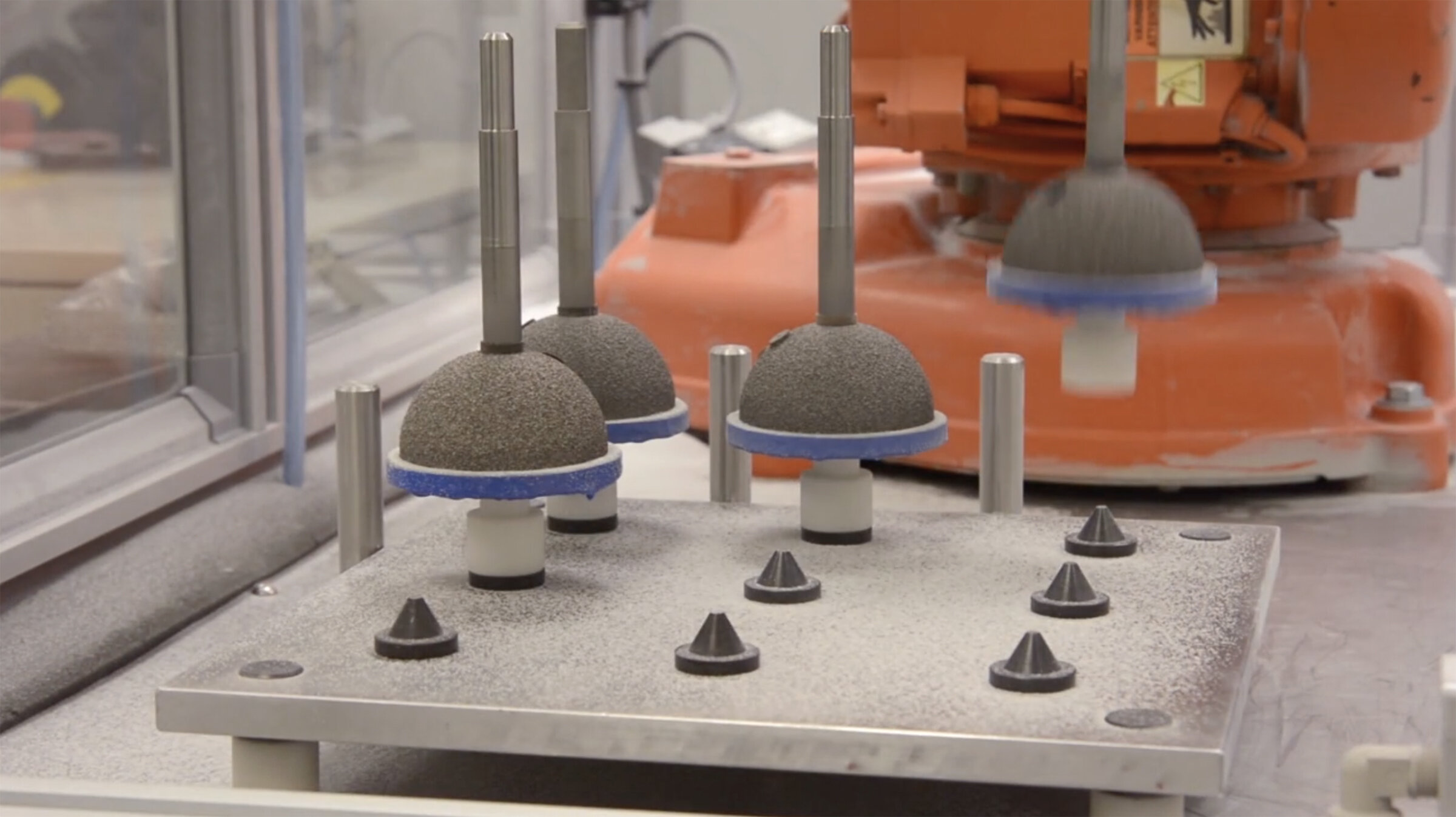

Meet xFAB: Himed’s Newest Fully Automated Blasting System

Discover how Himed’s newest in-house innovation, xFAB, enhances the precision, repeatability, and responsiveness of implant surface treatments across both R&D and production workflows. Built entirely by our engineering team, this fully automated system reflects our commitment to controlled, scalable, and regulation-ready processes.

Himed’s MCD Apatitic Abrasive Blasting Capacity Is Growing

Here at Himed, we just added a new member to our team of robots. We call it iFAB (short for “fully automated blaster”). It’s a highly-dexterous, automated industrial robot with six-axes of motion, that is contained within a new production cell. The iFab has been specifically designed to deliver our biocompatible MATRIX MCD® treatment to medical devices, dental implants, and orthopedic implants.

30 Years In The Making: Himed Gets Its Own Mailing Address

You know that saying, “If it’s not broken, why fix it?” Well, what if something isn’t necessarily broken but could be made better with a few simple changes? That’s exactly the way we saw our address system.

Himed was founded 30 years ago within the facilities of an aerospace coating provider called Hitemco. We’ve since expanded into our own nearby facilities and our business has grown to become a leader in the biomaterials industry.

Yet, through all these years, we’ve been using Hitemco’s shipping and receiving. That setup certainly wasn't broken but we realized we could streamline the process by implementing our own address.

Answering the Calls: 30 Years of Himed History

As President of Himed, Ed Garofalo oversees a business that’s now a leading global provider of cutting-edge biomaterials and surface treatments for the dental and orthopedic industries. Yet thirty years ago, if you went looking for Ed, you’d find him working with metal coatings for engine turbines at a family-owned business in New York called Hitemco.

Of course, engine turbine parts and a hip implant don’t have much in common on paper, but it’s safe to say that the finish on both had better be unquestionably precise before they’re put to use.

Better Medical Devices Through Automation

Sometimes when we think of automation, we get this idea of a rigid, inflexible machine stamping out mountains of cookie cutter products ad infinitum. An important part of our business at Himed is making customized products that meet very specific customer requirements, sometimes in small batches. The cookie cutter approach would never work for us.