Himed and Mercury Bio Team Up to Develop Unique Osteogenic Materials for Orthopedic Applications

Himed has entered a new realm of research this month with the formalizing of a research and development agreement with Santa Fe, NM-based Mercury Bio.

As a global supplier of calcium phosphate materials and implant surface treatments that support bone repair, Himed wishes to explore the frontiers of organic CaP integrations at the molecular level, and was seeking a partner with promising IP for small particle delivery. We were fortunate to find that partner in Mercury Bio, which has developed a novel advanced drug delivery system that could prove effective at also loading and targeting CaP compounds.

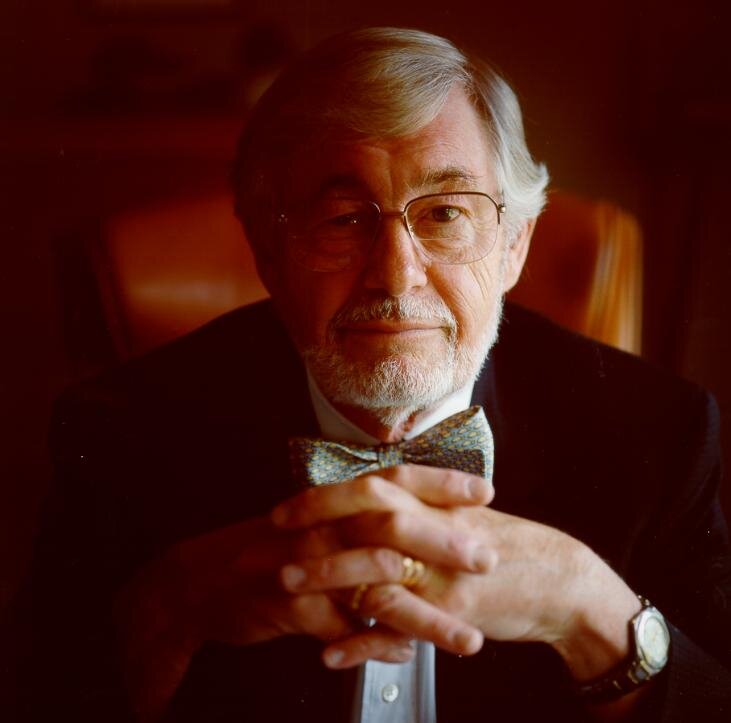

Titanium, Rabbits, and Tiny Microscopes: Dr. Brånemark’s Unlikely Discovery of the Modern Dental Implant

If you ever went searching for your car keys but found a $100 bill instead, you might feel a little like Dr. Per-Ingvar Brånemark. He was looking into how blood flow affects bone healing—and he ended up discovering osseointegration.

Better osseointegration is one of our primary goals at Himed. When we develop surface treatments and coatings, we do it with the aim of improving the integration of implants with a patient’s bones. The very phrase “osseointegration” was coined by Dr. Brånemark, who is now considered the father of the modern dental implant. Before his work, the medical community was pretty sure that such a thing wasn’t even possible.

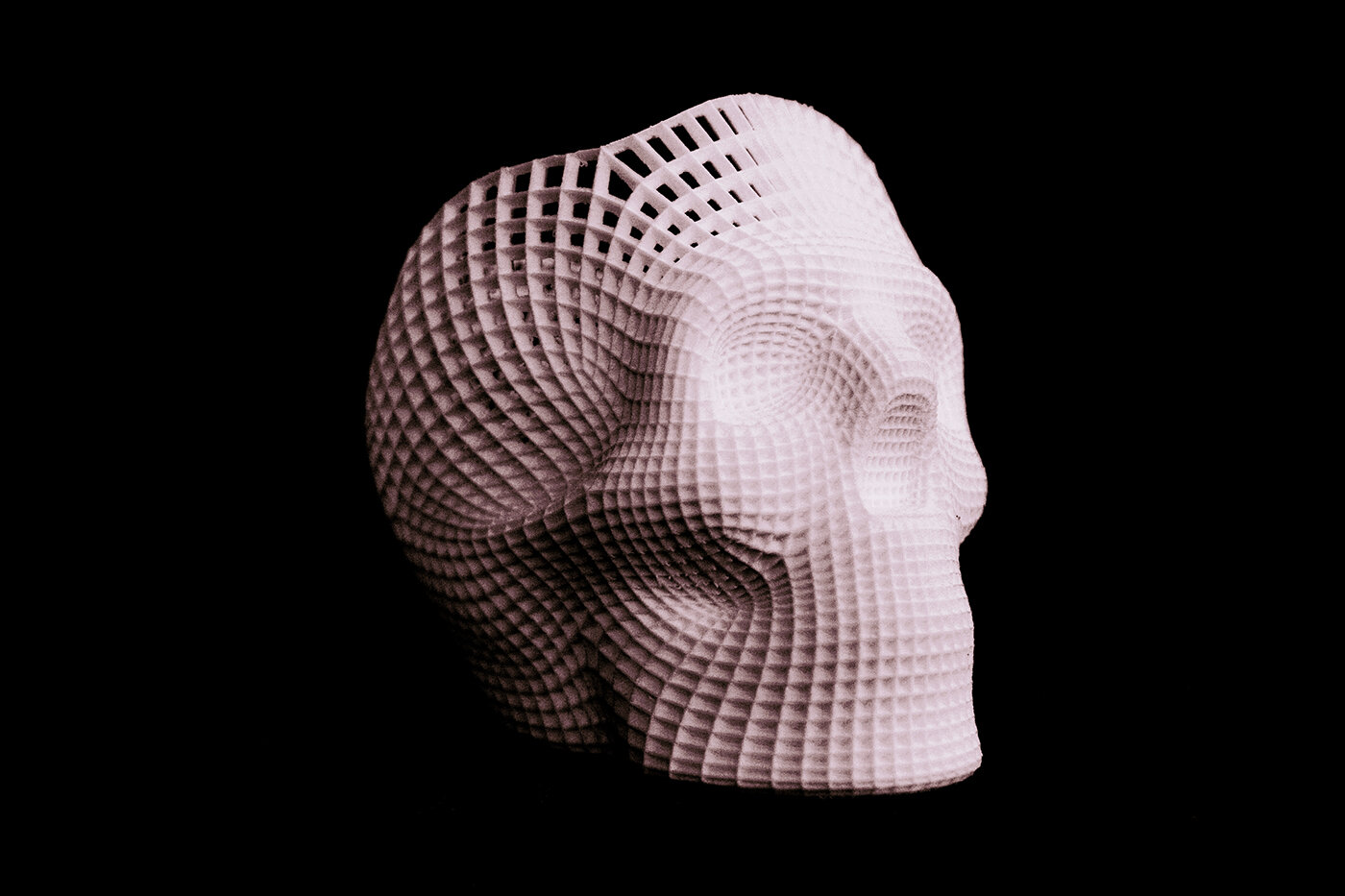

On the Path Towards 3D Printing Directly in the Body

Researchers at the University of New South Wales in Sydney have created a novel ink for 3D printing—one with major advantages for doctors and patients. The idea of 3D printing implants using biocompatible materials is not new. Here at Himed, we’ve been working to improve biocompatible calcium phosphate scaffolding agents for ten years, both to help patients today and in preparation for on-demand implant printing.

Answering the Calls: 30 Years of Himed History

As President of Himed, Ed Garofalo oversees a business that’s now a leading global provider of cutting-edge biomaterials and surface treatments for the dental and orthopedic industries. Yet thirty years ago, if you went looking for Ed, you’d find him working with metal coatings for engine turbines at a family-owned business in New York called Hitemco.

Of course, engine turbine parts and a hip implant don’t have much in common on paper, but it’s safe to say that the finish on both had better be unquestionably precise before they’re put to use.

Hipper than Ever: Advancing Technologies Make Hip Replacements Viable for a Younger Population

When you picture a typical hip replacement candidate, you likely think of someone aged 60 or 70, not 40 or 50. Up until recently, that assessment was in line with reality. The main reason older adults have been more likely to receive a hip replacement is fairly obvious: as people age, their joints are more likely to degenerate to the point where surgery is required.