Hydroxyapatite

A Key Calcium Phosphate for Hard Tissue Repair

Hydroxyapatite (HA) is a naturally occurring calcium phosphate, and the primary mineral found in human bone and tooth enamel. Its chemical and structural similarity to the hard tissues within our bodies gives it exceptional biocompatibility and bioactivity. These characteristics make HA one of the most studied and widely applied materials in bone regeneration, dental reconstruction, and orthopedic implant design.

Himed specializes in the production of high-quality hydroxyapatite powders, granules, and forms. We manufacture all of our hydroxyapatite under GMP guidelines that are in conformance with ISO 13485:2016—employing exacting chemical processes to ensure the uniformity, purity, and batch-to-batch consistency that our clients in the medical and dental markets require.

Himed’s hydroxyapatite conforms to ASTM F1185, with a composition of ≥96% pure hydroxyapatite, per XRD.

Unlike natural HA—which is extracted from animal or marine sources, and therefore subject to compositional variability—our synthetic HA provides a reproducible stoichiometric structure that can be precisely tailored to meet diverse clinical and engineering requirements. This level of control allows our team to optimize critical attributes such as particle size, crystallinity, surface area, and ionic composition.

Whether enhancing cellular adhesion in a scaffold, improving coating performance on a titanium implant, or tuning resorption behavior in a bone filler, Himed’s HA serves as a stable and adaptable platform for advanced biomedical applications.

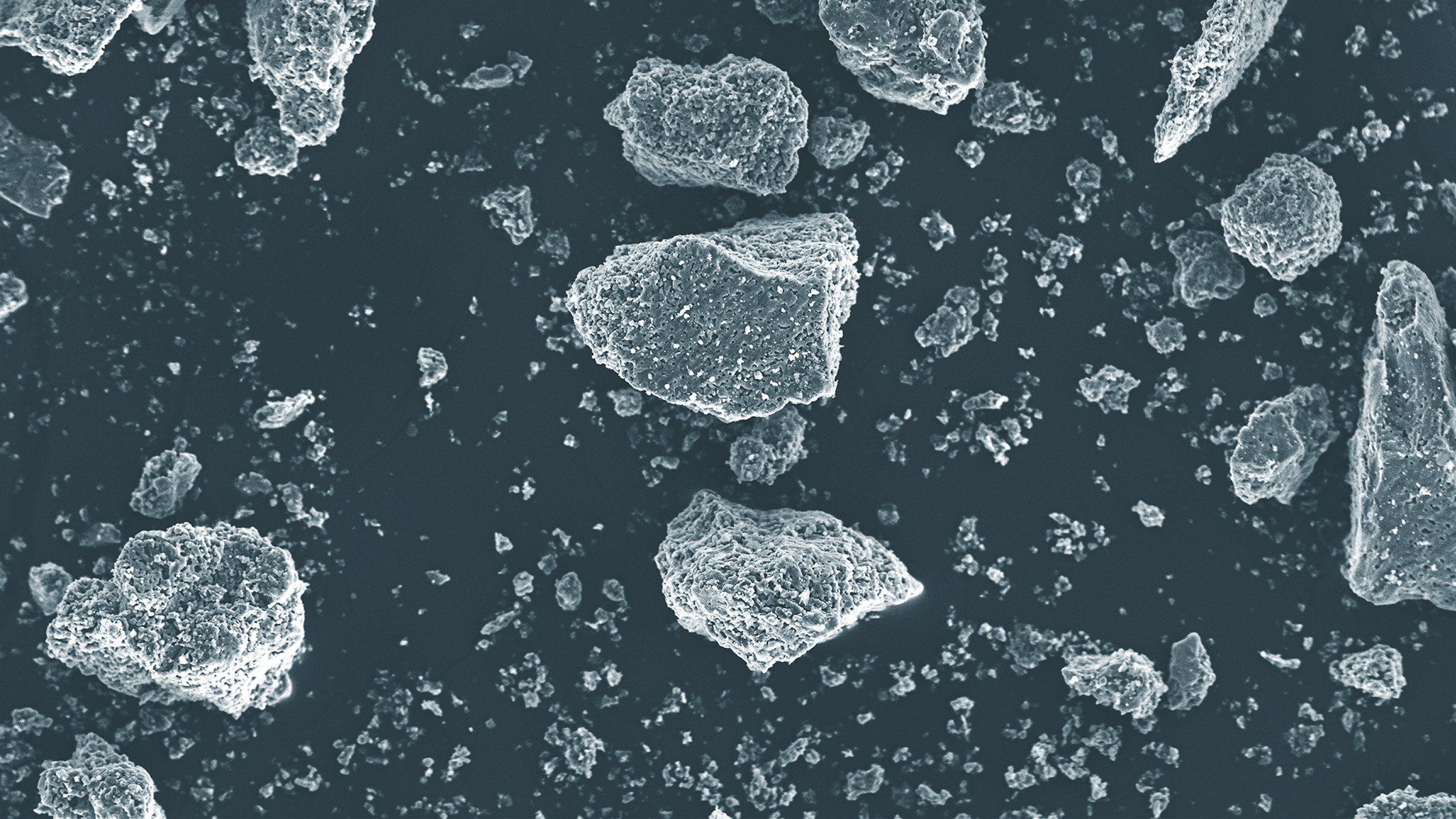

Himed manufactures hydroxyapatite in a variety of forms that include: powders (left), uniform or irregular granules, cast solids, or porous shapes (right). In addition to our catalog products, we provide analytical and testing services specific to calcium phosphates, and serve as a contract R&D partner to global medical device companies seeking customized forms of HA.

Himed is FDA registered with a Master File submitted for many of our HA processes.

Material Properties of Hydroxyapatite

Hydroxyapatite’s value as a biomaterial lies in its unique combination of biological affinity and tunable properties. As a synthetic analog of natural bone mineral, hydroxyapatite is highly biocompatible, osteoconductive, and chemically stable—making it ideal for applications where predictable integration with hard tissue is required. Himed produces hydroxyapatite under tightly controlled conditions to ensure reproducibility and enable tailored performance across orthopedic, dental, and laboratory use cases.

CORE MATERIAL CHARACTERISTICS

BIOCOMPATIBILITY: Non-inflammatory, non-immunogenic

OSTEOCONDUCTIVITY: Promotes bone ingrowth and osteoblast adhesion

SURFACE REACTIVITY: Supports matrix protein binding and early mineralization

POROSITY: Adjustable to support vascularization and cellular infiltration

SOLUBILITY: Low, but tunable for controlled resorption over time

Although hydroxyapatite closely mimics the chemical composition of natural bone, its mechanical behavior—particularly in its pure, sintered form—is more similar to cancellous (trabecular) bone than to dense cortical bone. While optimized HA composites can reach compressive strengths that approach the lower end of cortical bone performance, its inherent brittleness, low fracture toughness, and relatively modest elastic modulus prevent it from serving as a structurally sufficient material for most load-bearing applications on its own.

To overcome these limitations, HA is commonly integrated into composite or hybrid systems where it contributes bioactivity, while other materials provide the necessary mechanical strength. For example, various forms of HA can be combined with a high-performance polymer such as polyetheretherketone (PEEK) in a spinal fusion device. In such instances, HA plays a biologically active role—stimulating osteoblast activity, supporting matrix formation, and promoting device integration—while the structural substrate manages applied loads and mechanical stress.

Additionally, incorporating HA can increase an implant’s surface area and surface roughness, which are known to improve cellular adhesion, proliferation, and differentiation. This makes it a valuable component in engineered biomaterial systems that aim to balance biological interaction with mechanical reliability.

Diagram of hydroxyapatite whiskers, a unique rod-like form of HA, incorporated into porous PEEK (A), and dense solid PEEK (B), to improve biocompatiblity.

Customization Strategies for Hydroxyapatite

To meet specific clinical and engineering requirements, Himed offers a wide range of HA customizations, including:

Particle Size, Distribution, and Morphology

From nanopowder to coarse granules, available in spherical or irregular form, with narrow particle size distributions suited for grafts, injectables, or pastes.

POROSITY and Surface Area

Adjustable to optimize bioactivity, dissolution rate, and implant fixation.

MULTI PHASE COMPOUNDS

Integration with β-tricalcium phosphate (β-TCP), or other calcium phosphates phases, to create biphasic compounds that allow control over degradation rate, mechanical behavior, and biological signaling.

Unique Forms

Powders, granules, cast shapes, laboratory substrates (discs/coated slides), and 3D-printable formulations tailored for clinical, manufacturing, or analytical workflows.

Ion Substitution (Doping)

Trace elements such as magnesium (Mg), strontium (Sr), zinc (Zn), and silicon (Si) can be introduced to enhance osteogenesis, angiogenesis, or antimicrobial performance.

Through these engineered modifications, Himed’s synthetic hydroxyapatite can be precisely tuned to support a wide range of performance targets—from fast-resorbing scaffold fillers to structurally stable substrates for pre-clinical testing. Whether incorporated into composite systems or applied as a material platform for new device development, our HA delivers the predictability and flexibility required by today's advanced medical products.

Orthopedic Applications of Hydroxyapatite

In orthopedics, hydroxyapatite is widely used to promote bone regeneration, facilitate implant integration, and support long-term skeletal stability. Its chemical similarity to natural bone, combined with its proven osteoconductive properties, makes HA a reliable material for a range of reconstructive and load-sharing applications.

Powdered and granular forms of HA are commonly employed in synthetic bone grafts, void fillers, and composite scaffolds—particularly in trauma, revision, and reconstructive procedures where controlled resorption and predictable healing are essential. These forms can be packed into irregular bone defects or combined with other biomaterials to support site-specific outcomes.

In spinal and joint procedures, HA also reinforces interfaces between implants and host bone, helping reduce micromotion and supporting biological fixation. Emerging interfacial strategies, including the use of HA-enhanced cements, further expand its role in hybrid fixation techniques.

Hydroxyapatite also plays a critical role in implant coatings designed to accelerate early osseointegration. For more on Himed’s plasma-applied HA coatings, visit our MATRIX HA® Coatings page.

Dental Applications of Hydroxyapatite

Hydroxyapatite continues to expand its use across the dental sector, from implantable biomaterials to oral care products.

In clinical dentistry, powdered and granular HA is used in grafting procedures where it functions as an osteoconductive scaffold to support bone regeneration. It is also employed to augment bone around implants and in maxillofacial reconstructions requiring biocompatible, space-filling materials.

HA can be customized in many ways to improve the efficacy of bone fillers and cements commonly used in dental and maxillofacial repairs.

Beyond surgical use, HA in nanoparticle form is increasingly found in advanced oral care products, where it promotes enamel remineralization, reduces sensitivity, and supports a balanced oral microbiome. As both a bone substitute and bioactive surface material, hydroxyapatite remains a versatile material powering dental innovation.

Ready to explore using hydroxyapatite (HA) in your next project?

Connect with our materials engineering team to discuss which hydroxyapatite formulations, or potential customizations, might best align with your intended application.

Sample of precipitated and unsintered HA with a size range of <53 μm (Himed Catalog Code #UWHA20).