An Ideal Post-Processing Solution for Additive-Manufactured Medical Devices

Few things have been as potentially revolutionary for the medical device industry as 3D printing. The process allows implant manufacturers to design and produce innovative products quickly and efficiently. But additive manufacturing does introduce a few specific issues medical implant designers and fabricators must take into account.

Himed Announces New MATRIX Dual® White Paper Publication

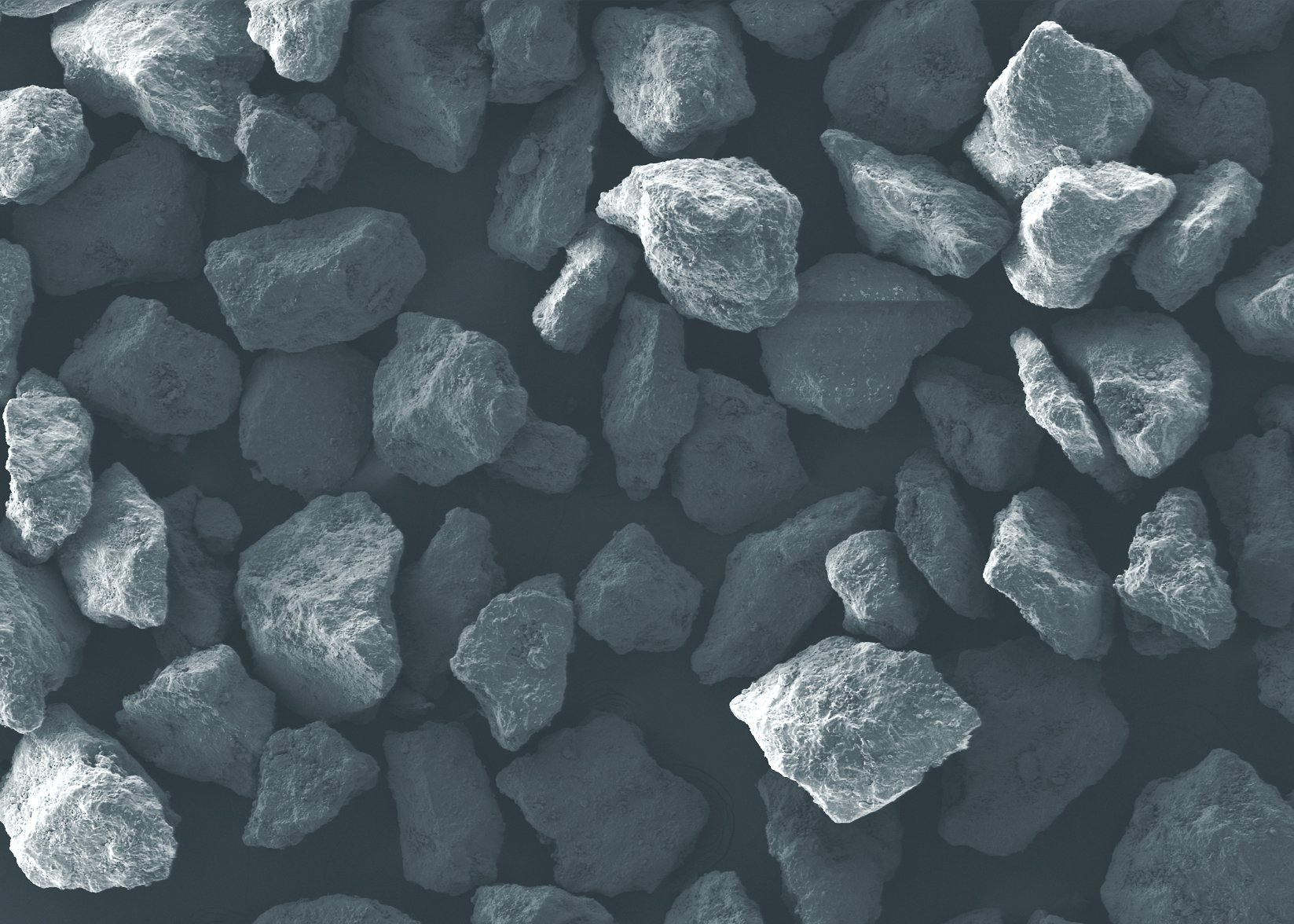

As the medical industry continues to explore the conditions for successful implant integration with the human body, closer attention is being paid to the surface morphology of a given device. That “closer attention” is taken quite literally in our latest white paper. In it, four case studies are reviewed that use advanced scanning technology to characterize—at the submicron and nanoscale level—surfaces treated with our two-step MATRIX Dual® process.

The Best Possible Outcome: The Importance of Post-Processing to Optimize Surface Morphology in Spinal Implants

Here at Himed, we are gearing up for the BIOMEDevice and the NASS trade shows in Boston. So we started asking ourselves what we were most excited about in orthopedic advancements in general, and spinal health in particular. The answer—perhaps not surprisingly for a surface treatment company—are the benefits that patients experience when spinal implants undergo optimizing surface treatments after manufacture.