An Ideal Post-Processing Solution for Additive-Manufactured Medical Devices

Few things have been as potentially revolutionary for the medical device industry as 3D printing. The process allows implant manufacturers to design and produce innovative products quickly and efficiently. But additive manufacturing does introduce a few specific issues medical implant designers and fabricators must take into account:

Excess Material: The existence of loosely adhered beads or excess build material from the printing process

Surface Texture: The necessity to create a uniformly textured surface, either for aesthetic reasons or to support specific biological functions in vivo, such as osseointegration

Maintaining Design Parameters: Using post-processing methodologies that avoid damage to the intended final shape of the device

In 2020, Himed published a white paper which addressed how Himed’s proprietary finishing process, MATRIX MCD® could address each of the above issues. MATRIX MCD®, which utilizes a unique apatitic abrasive, has the added benefit of never introducing bio-incompatible materials to the device.

Below is a synopsis of the white paper which uses data from three case studies to demonstrate how Himed has helped device manufacturers to improve their 3D-printed end product with post-processing. The complete white paper can be downloaded using the request form at the bottom of this post.

SEM image of Himed's MCD Apatitic Abrasive with size range of 425-180 μm (Cat#MCD160)

The importance of using a biocompatible blast medium

Decades ago, Himed pioneered the concept of a biocompatible, resorbable blast medium (RBM) when engineers utilized a specially hardened form of hydroxyapatite to finish the surfaces of titanium implants and devices.

Himed evolved that discovery into its MATRIX MCD® finishing process, which utilizes a granular, multi-phase calcium phosphate abrasive that is engineered to be as hard as possible. Combining the abrasive with an automated blasting system, the process creates complex, highly uniform macro and micro surface texturing on both cast and 3D-printed titanium alloy implants.

Traditional grit blasting methods utilize media such as aluminum oxide, which can leave behind embedded residue, even after acid bathing or other passivation methods. Unlike traditional grit blasting methods, surface finishing with Himed’s MCD Apatitic Abrasive leaves behind virtually no residue after passivation. And, if for some reason any MCD residue were to remain, it would be entirely biocompatible due to its composition of naturally occurring hydroxyapatite and other calcium phosphates.

In each of the studies below, all test devices were passivated per ASTM F86. This dissolved the soluble MCD Apatitic Abrasive and yielded a virtually residue-free, contaminant- free finish.

CASE STUDY #1

Removing excess beads on the additive build surface

This first case study focuses on the removal of residual beads from a 3D-printed titanium alloy acetabular cup: a component in an artificial hip replacement system. The cup is additively manufactured with a porous surface that provides initial mechanical fixation and long term biologic fixation.

In the creation of this porous surface, loosely adherent residual beads remain on the surface as a by-product of the additive manufacturing process. If the beads were to remain on the surface, researchers expressed concern that the titanium beads could become detached from the surface of the cup in vivo, potentially causing complications.

Himed’s study revealed that grit-blasting with MATRIX MCD® dislodged the beads, while providing the added benefit of further increasing the surface texture to create a more complex surface that could encourage osseointegration.

CASE STUDY #2

Removing surface abnormalities and defects on the additive build surface

In additive manufacturing, many devices are printed with a critical surface in direct contact with the additive build platform. Temporary support structures may also be required for more complex printing alignment. Both scenarios are likely to create surface abnormalities, or leave behind trace amounts of build material.

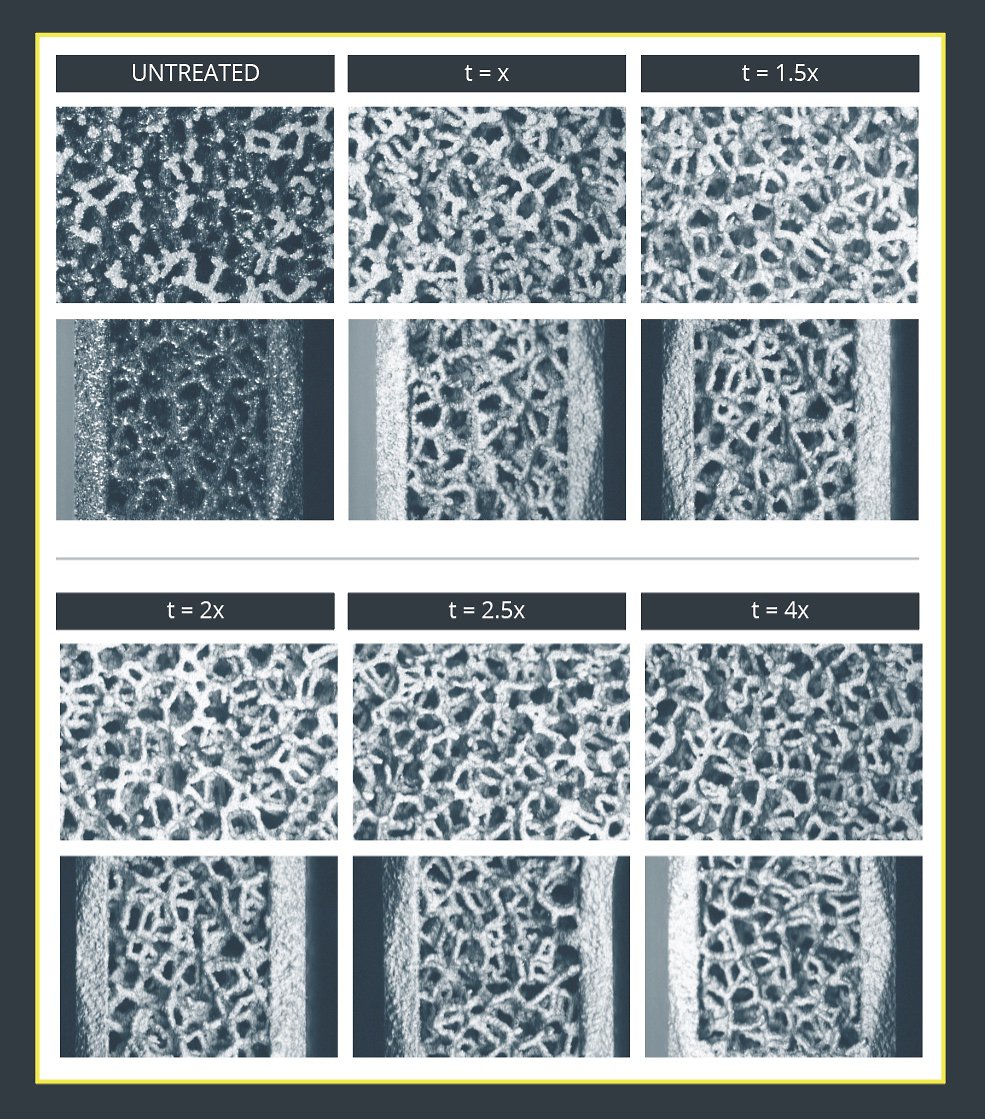

This case study analyzed additive-manufactured titanium alloy spinal spacers. Immediately following manufacture, the face of the implant that was in contact with the additive build platform showed pronounced surface irregularities when viewed under magnification.

The study subjected the spinal spacers to MCD grit-blasting, analyzing the surface after increasing intervals of time. With increased exposure to the grit-blast process, the surface defects and imperfections were eliminated. The overall surface of the device then showed an optimized, uniform texture, rendering the device ideal for implantation.

With increased grit-blast time via Himed’s MATRIX MCD®, the surface of these additive manufactured spinal spacers becomes more uniform and imperfections are removed

CASE STUDY #3

Maintaining surface profile in post-processing

One of the benefits of additive manufacturing is the ability to produce highly detailed and accurate device shapes. Therefore, it’s important that post-processing methods don’t alter the overall shape of the product.

The third case study quantitatively characterized surface profiles after MATRIX MCD® grit-blasting by analyzing roughness, height, shape, and high spot count parameters using laser profilometry.

The study involved additive manufactured, flat, non-porous surfaces, and divided the surfaces into four different test groups. The first was a control group, with the subsequent three groups subjected to increasing intervals of grit-blasting time. Process factors such as blast distance and pressure were maintained for each of the three grit-blasted groups.

After blasting and evaluation, the control surface showed the highest degree of roughness and surface variation. Each of the grit-blast-treated surfaces showed increased micro-texture and a more uniform macro-textured surface.

Measuring kurtosis, or sharpness of the roughness profile, revealed that the blast was effective in creating a uniform surface, but it did not overly blunt the peaks beyond a gaussian shape. Minimal change was also shown for the skewness, or the degree of symmetry of the surface peaks and valleys. The high spot count values, which measure the largest peaks and surface irregularities, were reduced by 50 percent, even with the shortest blast time interval.

This study revealed that the blasting process removed minimal material while preserving the dimensional accuracy that’s critical for device performance. For complex designs that seek to preserve original surface features, custom masking can be used to selectively treat specific regions of the device.

Optimizing additive-manufactured devices while maintaining shape and biocompatibility

Additive manufacturing offers rapid prototyping technologies and mass production of implantable devices, all with a low cost and quicker lead time. Finding the right post-processing is critical for the best end-patient outcome. Himed’s MATRIX MCD® finishing process has been demonstrated to offer optimal surface texture while eliminating common concerns resulting from the 3D printing process.

To see more imagery and detailed data from these studies, use the form below to request a copy of the Finishing 3D Printed Devices with MATRIX MCD® Apatitic Abrasive white paper. Or call our engineers today to discuss post-processing options for your additive manufactured devices.