Al2O3, Glass Beads, and Apatitic Abrasive: Comparing Post-Processing Options for 3D-Printed Titanium Medical Implants

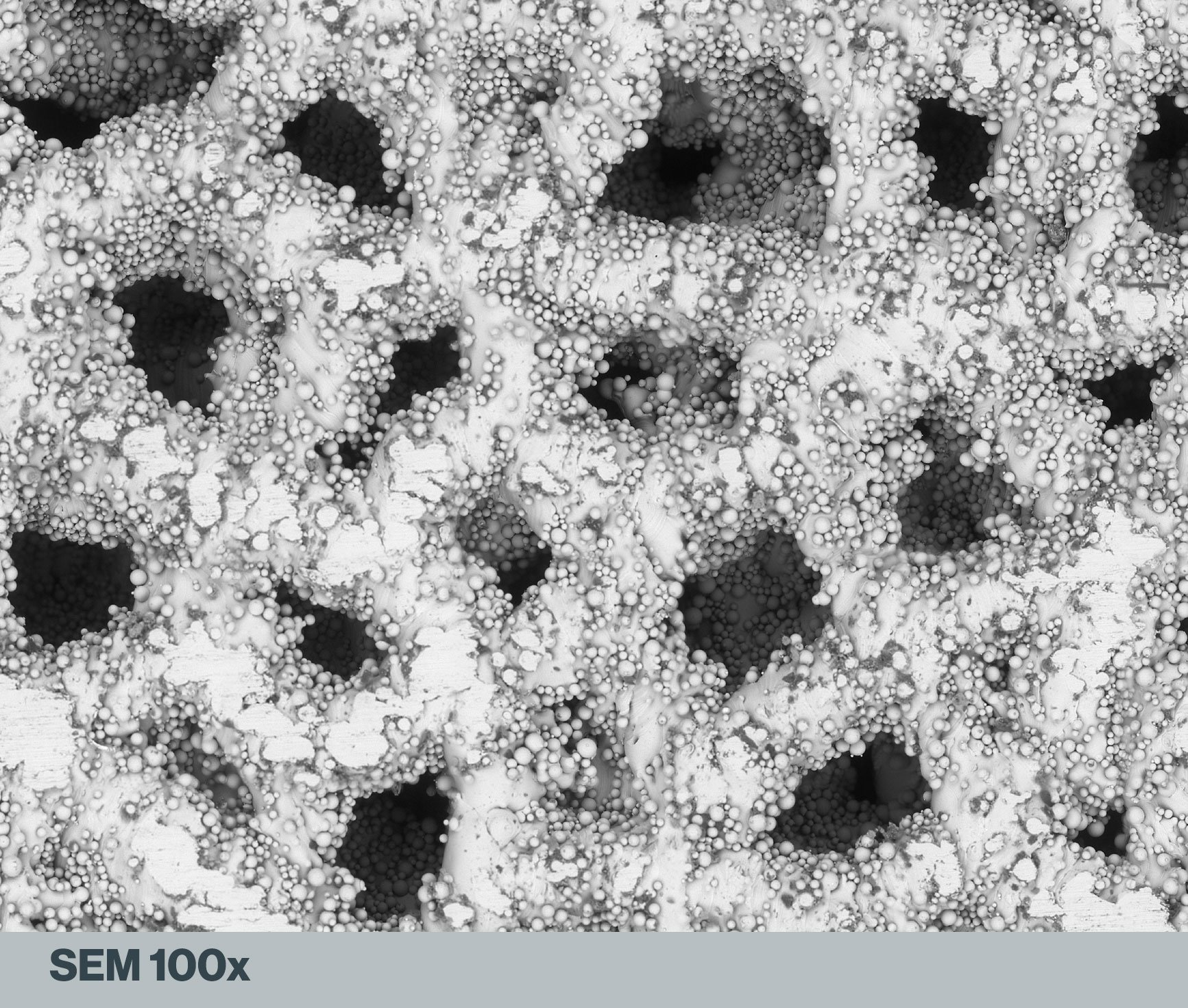

For the best chance of successful osseointegration, titanium and titanium-alloy implants need to undergo a surface finishing process. Research has shown that specifically textured surfaces on Ti implants can increase bone-to-implant contact and encourage new tissue growth around the device.

Himed’s MCD Apatitic Abrasive Blasting Capacity Is Growing

Here at Himed, we just added a new member to our team of robots. We call it iFAB (short for “fully automated blaster”). It’s a highly-dexterous, automated industrial robot with six-axes of motion, that is contained within a new production cell. The iFab has been specifically designed to deliver our biocompatible MATRIX MCD® treatment to medical devices, dental implants, and orthopedic implants.

White Paper on Finishing 3D Printed Titanium Implants

While 3D printing has transformed the rapid production of intricate implantable devices, post-process finishing is often a necessity for critical improvements to the aesthetic appearance and overall functionality. MATRIX MCD® Apatitic Abrasive micro-blasting presents an efficient and highly effective option!

This whitepaper, published by ORTHOWORLD® in the latest BONEZONE/OMTEC eNewsletter, reviews multiple case studies to demonstrate these advantages.