Explore Himed’s MATRIX Surfaces

For over 30 years Himed has been at the vanguard of biocompatible surface texturing and coating solutions.

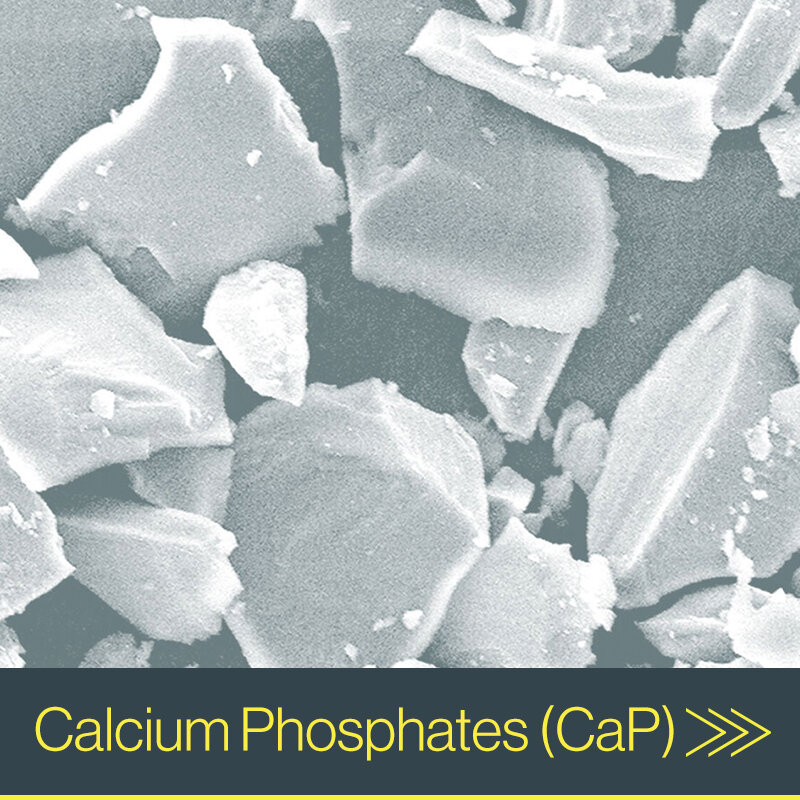

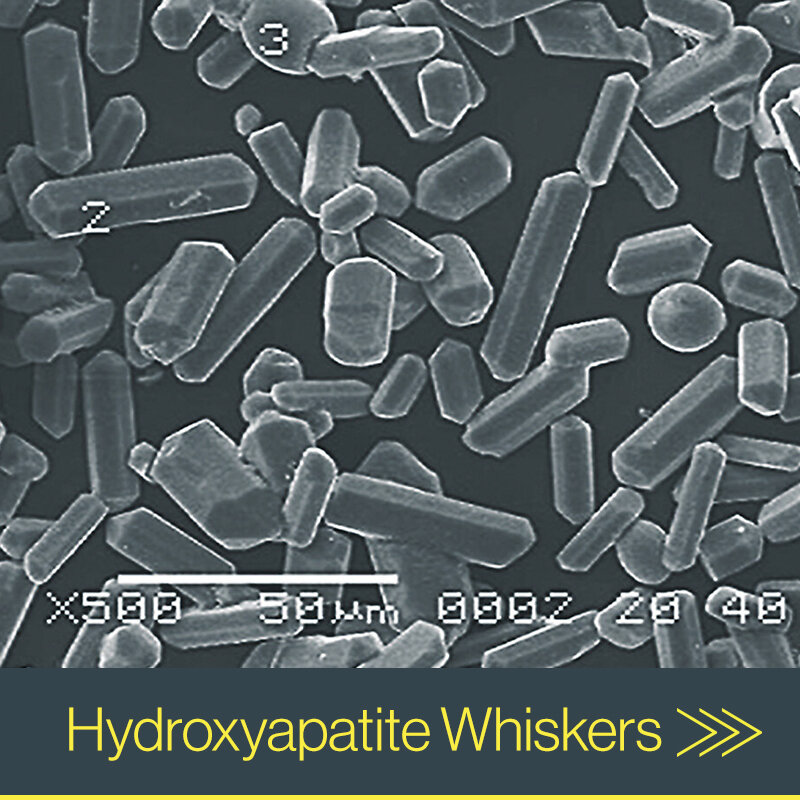

Beginning with early innovations for uniform applications of hydroxyapatite on medical implants, Himed soon developed the world’s first CaP-based resorbable blast media, MCD Apatitic Abrasive, which is used on millions of implants annually across the globe.

Whether your company is looking to enhance the performance of an existing implant device, or is in the early stages of designing an entirely new medical product, Himed can provide expertise, analysis, and exacting surface treatments to help you achieve your goals.

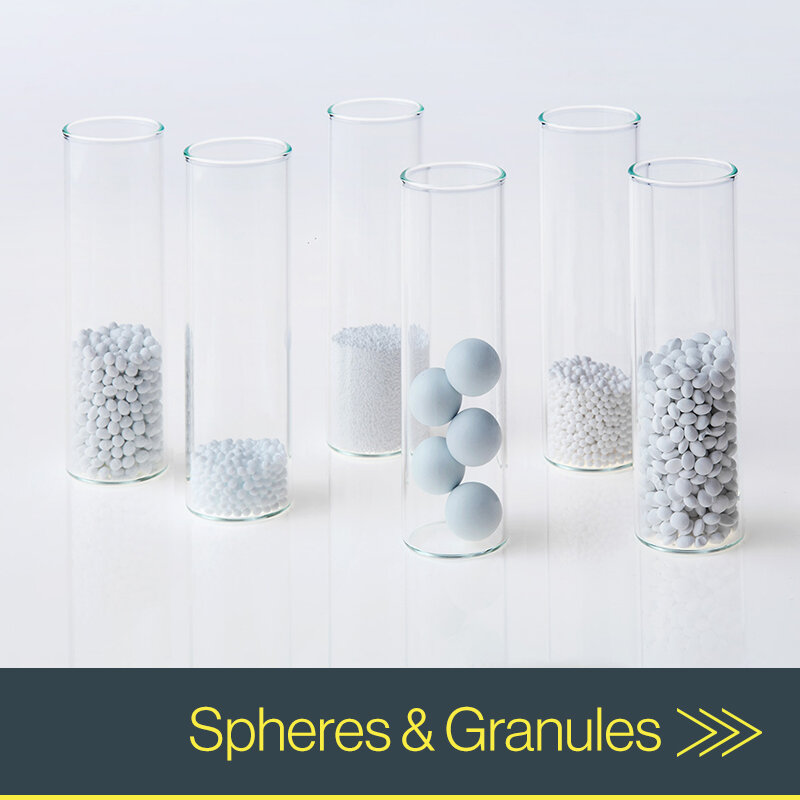

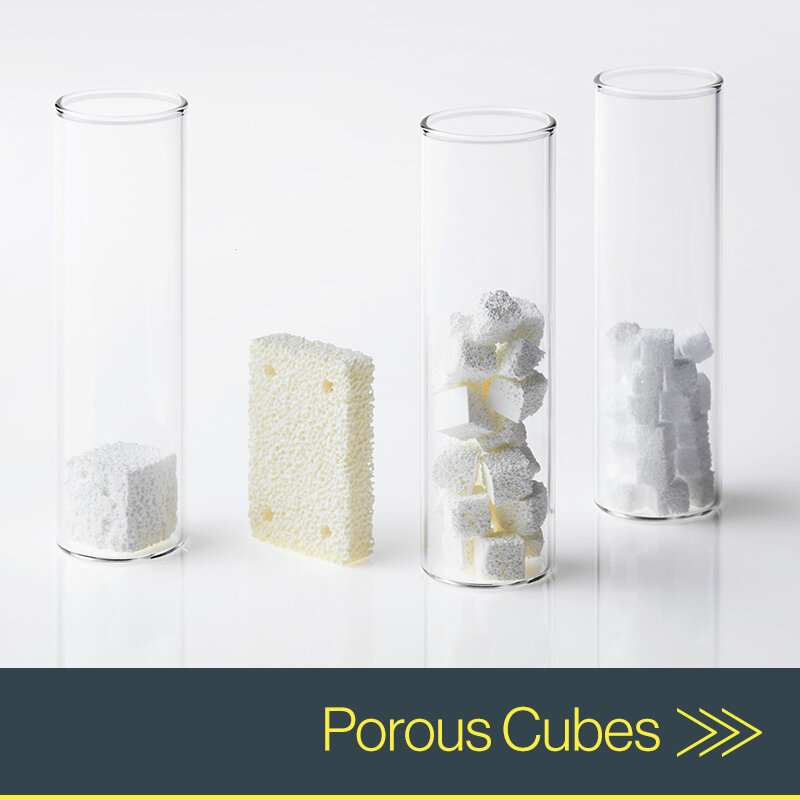

View our MATRIX® offerings via the quick links below, or contact us directly so that we can explore the possibilities together.

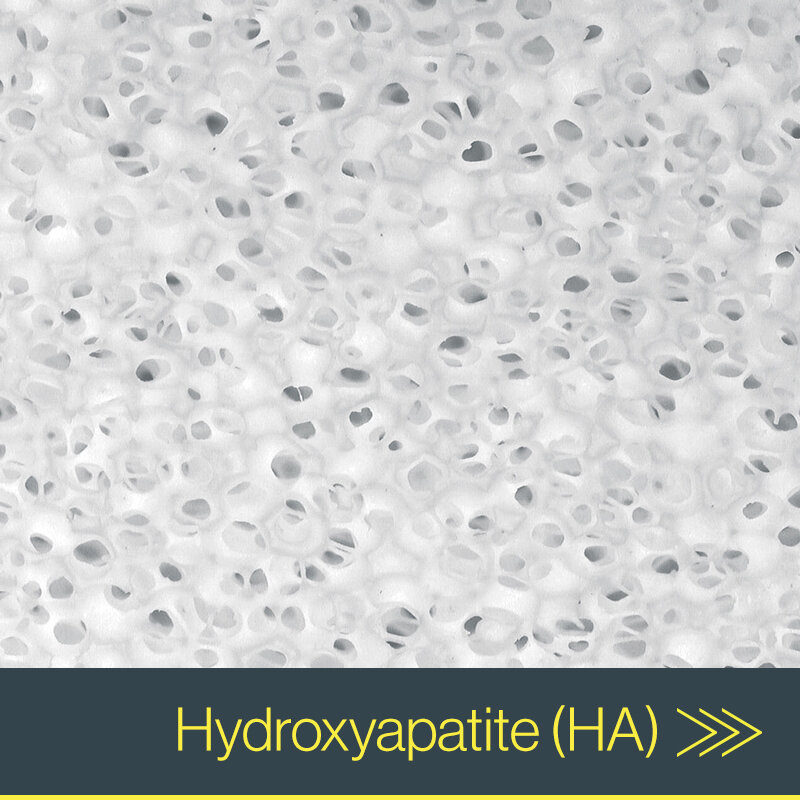

Hydroxyapatite Coatings

Himed was among the first companies to develop an air-plasma-sprayed hydroxyapatite (HA) system, and we’ve been innovating HA coating technologies ever since.

Variables such as coating thickness, phase composition, crystallinity, and application zones ensure that our hydroxyapatite coatings meet your specific needs while exceeding applicable ASTM, ISO, and FDA standards.

Type III Color Anodizing

Biocompatible color anodizing offers device manufacturers exacting control over the visual presentation of their product while also creating options for finishes that aid in simplified part identification.

Custom masking of treatment areas allow for very specific application of the sanitary colored surface.

Cost-Effective Titanium Coatings

Our patented titanium coating process simplifies the application of Ti, avoiding costly conventional vacuum applied methodologies in favor of a unique air-plasma spray solution. The result? Highly-textured Ti surfaces with less cost and faster production times.

Biocompatible Apatitic Abrasive Blasting

Optimizing an implant for osseointegration often requires abrading the titanium surface with an abrasive, but conventional carbide grit-blasting can leave harmful contaminants embedded in the surface. That’s why Himed formulated a resorbable blast media from calcium phosphates which eliminates the risk of contamination altogether. As additive manufacturing of implants increases, our MATRIX MCD® process becomes even more important for removing residual material and creating a uniform implant finish.

Additional Resources

Here are a few helpful links exploring the benefits of our assorted MATRIX® surfaces for orthopedic and dental implants…