Al2O3, Glass Beads, and Apatitic Abrasive: Comparing Post-Processing Options for 3D-Printed Titanium Medical Implants

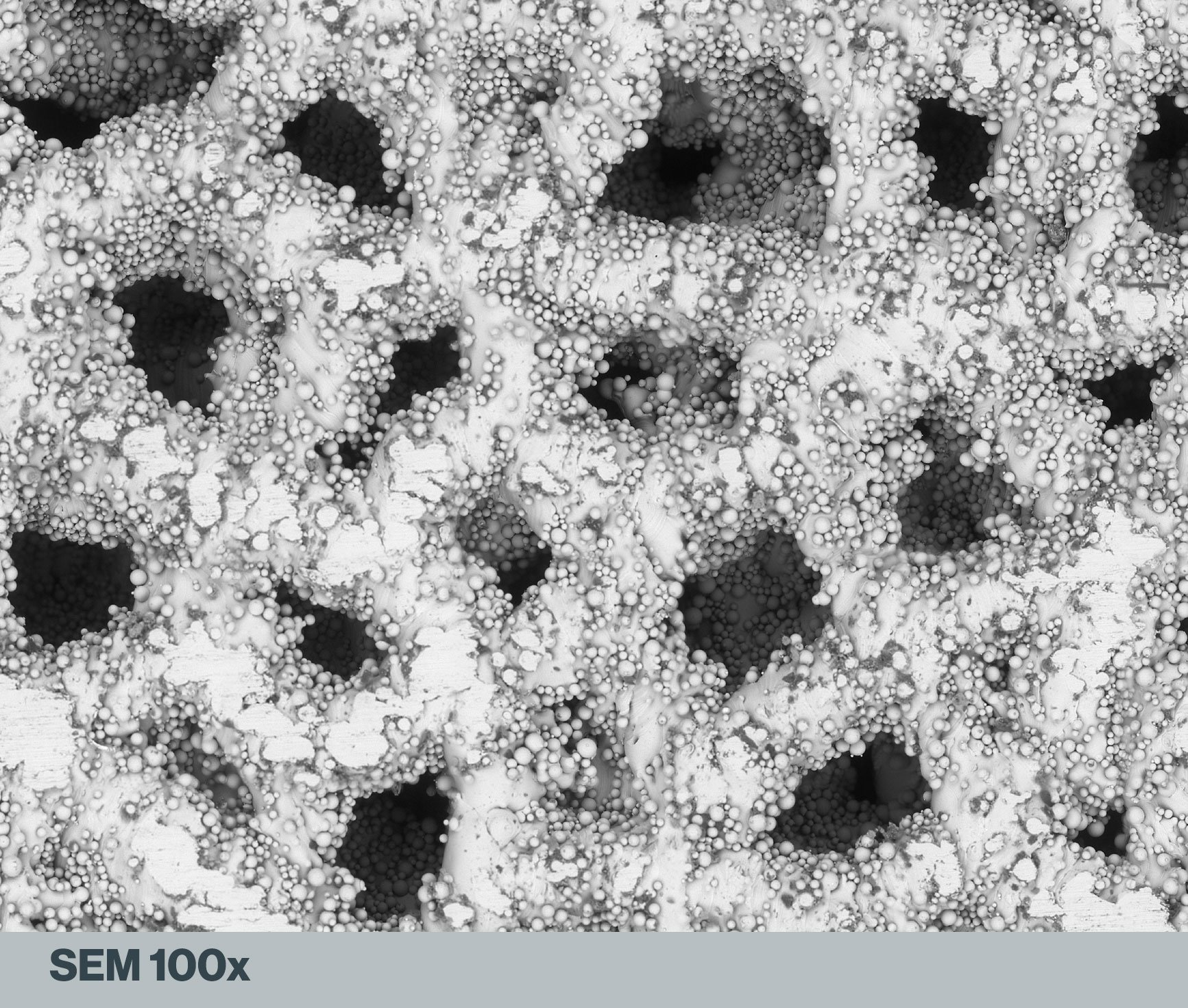

For the best chance of successful osseointegration, titanium and titanium-alloy implants need to undergo a surface finishing process. Research has shown that specifically textured surfaces on Ti implants can increase bone-to-implant contact and encourage new tissue growth around the device.

White Paper on Finishing 3D Printed Titanium Implants

While 3D printing has transformed the rapid production of intricate implantable devices, post-process finishing is often a necessity for critical improvements to the aesthetic appearance and overall functionality. MATRIX MCD® Apatitic Abrasive micro-blasting presents an efficient and highly effective option!

This whitepaper, published by ORTHOWORLD® in the latest BONEZONE/OMTEC eNewsletter, reviews multiple case studies to demonstrate these advantages.