My company wants to buy hydroxyapatite from a new supplier—will it be the same as what we’ve been using?

By: Esther Valliant, PhD - Biomaterials Research Scientist, Himed LLC

ASK A BIOMATERIALS SCIENTIST offers real-world insights into questions about medical biomaterials like hydroxyapatite, β-TCP, and other calcium phosphates. Have a question you’d like answered in a future post? CONTACT US

There is no single form of hydroxyapatite (HA, or HAp) that is used universally for all applications, so the short answer is no.

But that doesn’t mean that you can’t find a suitable equivalent, or even a better form, based on your intended application. With so many uses now for hydroxyapatite across a wide range of industries, it’s safe to assume that every company has unique needs and requirements that must be met when sourcing a new vendor.

If you’re considering a change in biomaterials suppliers, the steps below offer a logical methodology for identifying the key qualities of the material you’re trying to match. With that information, you’ll be able to more clearly convey your needs and get the results you want from a new provider.

STEP 1: Understand the Composition of What You’re Trying to Match

COMPOSITION

When sourcing a raw biomaterial, you’re going to begin by looking at the composition of what you’ve been using. Is it 100% HA? Well, that probably means >95% HA, with the other approximately 5% being composed of other calcium phosphate phases and trace elements. Maybe you’ve been using a mixture of HA and β-TCP (beta tricalcium phosphate, or b-TCP)? That’s a mixture we see a lot for bone repair applications due to the bioresorbable nature of β-TCP. The composition of your current material should be documented clearly on a product specification sheet provided by the manufacturer.

At Himed, we have detailed specification sheets for all of our raw biomaterials, and this is often the first request a company makes when exploring whether they want to work with us, because they want to compare compositions.

Request product specification sheets from the biomaterials supplier you’re researching, and compare them against the specification sheets of your current supplier.

PARTICLE SIZE & DISTRIBUTION

Particle size is another important property to identify when trying to match a biomaterial like hydroxyapatite. You may already have a very specific use for this material and be applying it in a very specific manner—a dramatic change in particle size can wreak havoc on the systems you’ve carefully calibrated, so it cannot be disregarded as a factor. That being said, comparing particle size isn’t always apples to apples:

Let’s say the powder you’re using is indicated as 100-300 microns. But in reality, it’s not going to be 100% 100-300 microns—there’s a distribution. Characterizing that distribution might be key to getting good results from another supplier’s powder of a similar particle size. The closer you can get that distribution to match, the less likely you are to run into performance problems and surprises when applying powder from a new supplier within your current systems.

SHAPE & SURFACE AREA

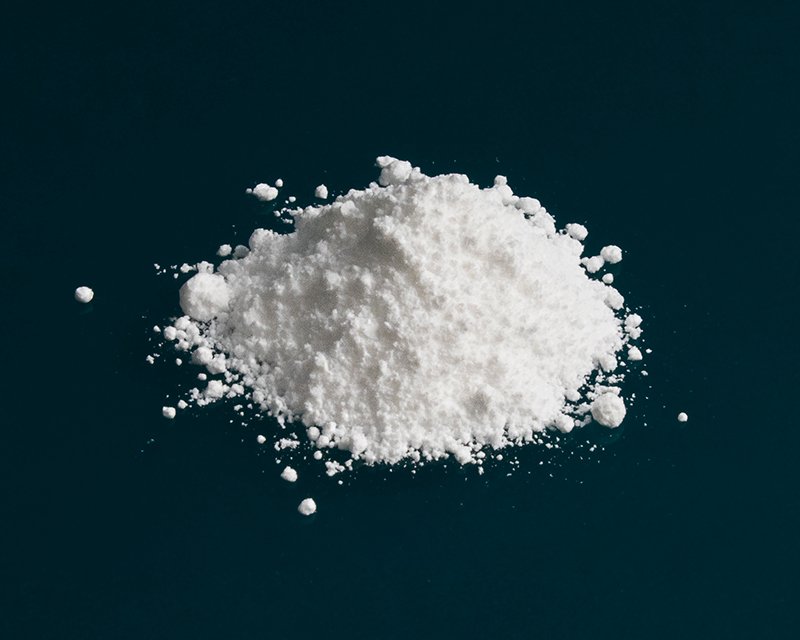

The final composition factor that can be helpful to understand is the actual shape of the particle you’re trying to match. Most people can’t immediately discern huge differences in the qualities of powders milled to equivalent sizes when looking at them with the naked eye. So if you look at something under a microscope, is it a gravel-shaped particle? That means it has hard edges. Or maybe the particles are lumpy with lots of tiny voids? That’s a material that has a much higher surface area.

Those differences in shape can have a big impact on factors like osteoconductivity or the in vivo dissolution rate of a material. The surface area of the powder can be measured using BET Nitrogen sorption. However, to visualize the particle shape requires viewing physical powder samples with a scanning electron microscope (SEM). That can be an involved process, which is why we’ve opted to put SEM images of our biomaterials directly on our specification sheets so that anyone who requests them can immediately see the shape and surface structure on the particles for each material.

Just imagine that you’re a cell, and you want to attach to a surface. Cells usually like things with surface roughness and texture. It gives them more places to attach by providing little crevices where they prefer to grow. Materials with this type of surface have an overall higher surface area.

Consider this too: a different surface area will change how a material mixes. For example, if you’re mixing a biocompatible powder with a polymer to make a bone putty, that surface area of the powder will change the mixing behavior, uniformity, and the particle retention of the biocompatible phase in the biocomposite. The biocompatible powder particles exposed on the surface encourage cell attachment and osteointegration.

Hydroxyapatite is similar to the mineral component in natural bone, and its ability to promote osteointegration is one of the biggest reasons it’s being used so much in dental and orthopedic implants, but there’s a lot of variety across hydroxyapatites (see the above image), and those variations have real effects on cellular adhesion and bone integration.

In short, conducting a basic analysis of the physical properties of the biomaterial you want to match is a good starting point when sourcing a new supplier. The next step is to try and understand how that biomaterial is manufactured.

STEP 2: Clarify the Method of Manufacture

How hydroxyapatite and other calcium phosphates are manufactured has a direct impact on their physical properties and potential applications. Knowing whether a powder you’re trying to match was manufactured using a high-temperature sintering process or a precipitation process could help eliminate another variable, and it could speed up the testing process for a replacement material.

Comparison of hydroxyapatite that is precipitated and unsintered (top) and a version that is precipitated and sintered (bottom) immediately shows how the process of manufacture can impact particle distribution and potential flowability.

If the specification sheet you have from your current supplier doesn’t provide the method of manufacture, take a look at any past Certificates of Analysis that you may have received for the material. Sometimes that information can be found there.

Many suppliers aren’t particularly open about their method of manufacture. At Himed, we’ve opted to put that information front and center on our specification sheets, but other companies can treat it like a trade secret. Thankfully, there are some observable properties and basic tests that can be conducted by companies like ours which help reveal this bit of information if you can’t find it elsewhere.

STEP 3: Communicate Directly with the Technical Team of a Potential Supplier

As a matter of efficiency, nothing beats having a direct conversation with a member of the potential supplier’s technical team or leadership. In some cases, it’s hard to even get specification sheets by which to compare materials without taking this step. Frankly, it’s just a good thing to do early on in the process of evaluating another supplier. The company you select might end up being a business partner for decades, and you want to get a sense of who they are, what they value, and how they behave right away to see if they’ll be a good fit.

Be candid about the product you’ve been using and what specific performance parameters you’re seeking from a replacement. Share as much about the composition of the biomaterial as possible so that the potential supplier can quickly determine whether or not they could even match it. The more information provided, the more forthcoming they can be about what is similar, or different, about their material. If you require an NDA before discussing anything in detail, just say so and provide it so that the dialogue can move forward with clear understandings.

At the end of the day, there’s an important human element to any business relationship—if you’re seeking a material that’s critical to your success, then clear communication, reliability, and trustworthiness cannot be overstated. If a supplier can deliver on those things, that has a real financial value that should factor into any cost analysis you do.

STEP 4: Test Samples Within Your Existing Systems

If you reach a point where you believe a supplier could provide a good equivalent—or better alternative—to the material you’re currently using, then it’s time to begin testing. Order a small quantity and test it in your process. Then do that again many times, ideally using different batches of the sample material from the potential vendor each time so that you can compare results.

You’ve likely already optimized the system that will be using that material to produce a specific product or outcome—testing allows you to identify how good a fit the replacement material might be. The more it performs like what you’ve used before, the less you’ll have to adjust a process that already works. Testing samples from different lots/batches of the same material, and assessing the consistency of the results, can reveal how uniform the quality of the material actually is from the potential supplier. Consistency of performance is key!

Speaking from experience, powders can be really tricky. Even slight changes in composition are capable of creating significant disruptions in pre-existing systems. It’s critical to find a new supplier that is willing to understand your production methodologies and intended outcomes. They should be able to offer material solutions that match the scale at which you’re operating—adjusting powders for optimum flowability if your production volumes are high, for example. They should be able to identify the differences that might be needed according to your final objective: after all, a hydroxyapatite powder for a plasma spray coating is very different from the hydroxyapatite that will be part of the bioink used to 3D-print a spinal implant.

Seeking Help with Biomaterial Characterization

At this point, you might be wondering whether it’d just be easier to have a sample of the current material professionally analyzed before beginning the process of sourcing other potential suppliers.

For companies with large in-house scientific teams and the right equipment, perhaps not. But at Himed, we receive many such requests from start-ups to midsize companies precisely because we have a lab space specifically designed for such material characterization—not to mention a 30+ year focus on customizing biomaterials.

We understand the various outcomes people are seeking from these materials because we manufacture and customize them for companies around the world. If you’d like to explore having Himed’s help, just contact our technical team:

Without question, adding a new materials supplier requires time and effort if it's done correctly. Clearly understanding the qualities of the material you want to source, and the outcomes that material is intended to elicit, are the most important pieces of data you’ll need. If a potential supplier isn’t interested in those details, talk to someone else!

About the Author

Esther Valliant has focused on biomaterials for hard tissue applications and developing new medical devices for the past 15 years. Her education includes an undergraduate degree in Chemical Engineering from Queen’s University (Kingston, Canada), a PhD in Material Science from Imperial College London (London, UK) and a Post-doctoral fellowship in Biomedical Engineering at Dalhousie University (Halifax, Canada).