A New 3D-Print and Biomaterials Research Center from Himed

The Bioceramics Center of Excellence™ Combines Himed’s Expert Materials Engineering Guidance with Rapid Prototyping of Medical Implant Designs via Lithoz 3D-Printing

The era of implantable medical devices leveraging the regenerative potentials of bioceramic materials is upon us. Enabled by the manufacturing precision of 3D-printing, and ongoing developments in printable bioinks, a new frontier of highly customizable, print-on-demand, orthopedic and dental devices promises to dramatically improve patient outcomes.

To accelerate these developments, Himed and Lithoz, two companies renowned in their respective sectors for vanguard thinking, have joined forces to deliver a contract research experience that will enable companies of all sizes to test their device design concepts, and refine them in a workflow conceived to scale gracefully into production.

Ready to design the future? We’re here to help.

LOCATION:

Part of Himed’s 25,000 sq. ft. facility

Old Bethpage, NY - USA

CERTIFICATIONS & REGISTRATIONS:

Accelerate Your Medical Implant R&D with Advanced 3D-Printed Prototyping

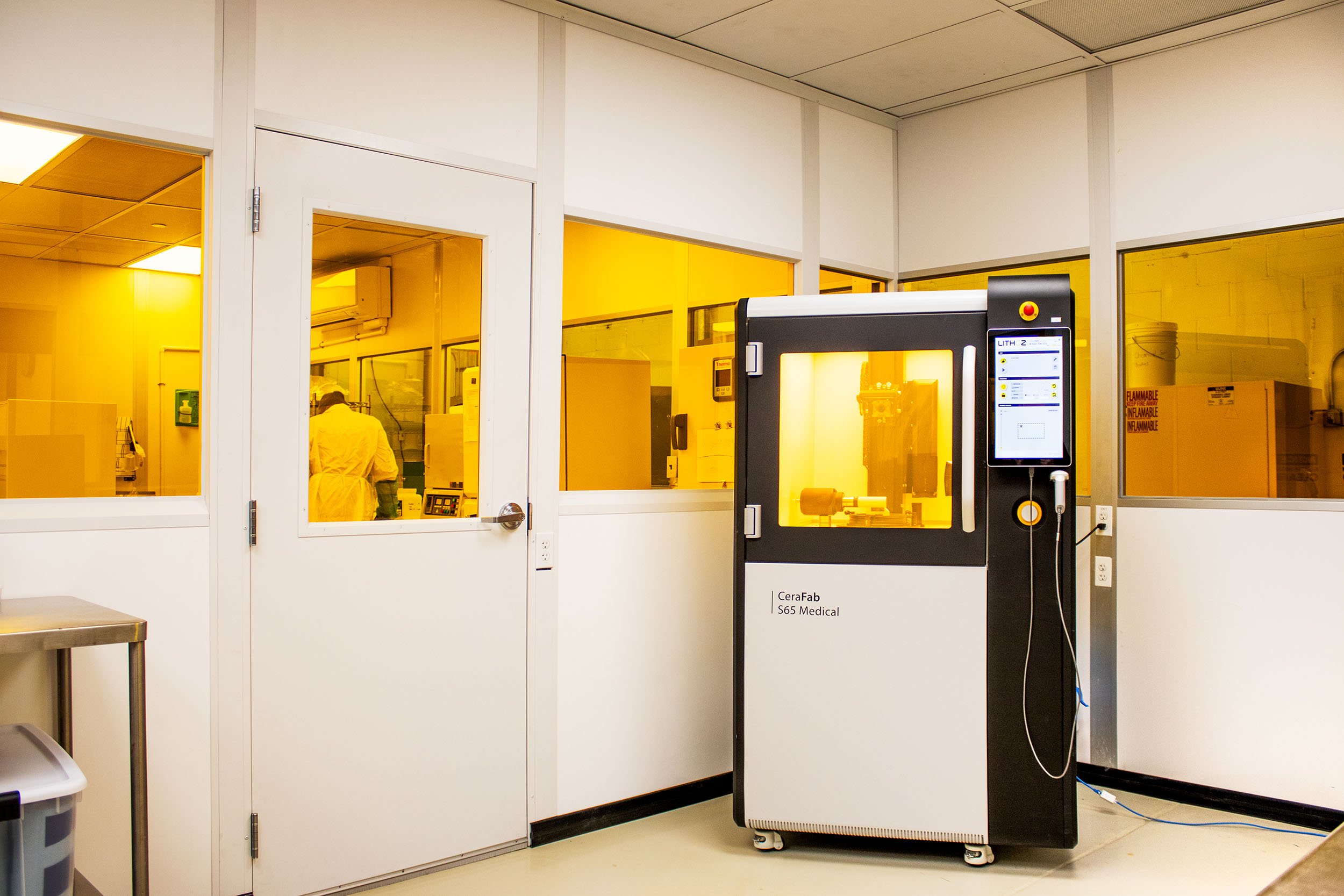

Lithoz's CeraFab S65 Medical 3D printer powers the prototyping capabilities at the Bioceramics Center of Excellence™ (BCoE). Employing Lithography-based Ceramic Manufacturing (LCM) technology, the CeraFab S65 Medical can rapidly generate and iterate individual prototypes and provide precise serial production of finalized designs. The LCM technology ensures accuracy and quality in printed bioceramic components, enabling the complex geometries and intricate designs that are often essential for medical applications.

Access to the CeraFab S65 Medical printer at the BCoE lets medical device designers test and refine their ideas quickly and effectively. This particularly benefits startups and smaller teams lacking the resources to invest upfront in 3D printing equipment while establishing proof of concept. Instead, through the BCoE, companies leverage the expertise of Himed and Lithoz's engineers to explore new compositions and 3D-printing techniques before committing to an expansion into additive manufacturing.

Lithoz’s LCM technology is unsurpassed in print fidelity and is designed to minimize material waste.

Integrated Analytical Services for Superior Materials & Device Characterization

The analytical services at the BCoE form a cornerstone of its comprehensive R&D offering. Leveraging Himed's 30+ years of experience in biomaterial analysis, the center provides advanced techniques such as high-powered surface imaging, topography analysis, chemical analysis, and stress testing. These services are crucial for characterizing the properties and performance of bioceramic prototypes, ensuring they meet the stringent requirements of medical applications.

The BCoE offers a cost-effective and generative R&D process by combining rapid prototyping with robust analytical capabilities. This integrated method allows for continuous documentation of progress toward intended outcomes, providing valuable data and proof points for market entry. Medical device manufacturers can rely on the BCoE to deliver comprehensive insights that support their validation steps.

With a dedicated team specializing in biomaterials characterization, Himed delivers the data you need to make informed decisions throughout your R&D process.

BCoE ANALYTICAL CAPABILITIES

SCANNING ELECTRON MICROSCOPY (SEM)

energy-dispersive X-ray spectroscopy (EDS/EDX)

X-Ray Powder Diffraction (XRD)

ICP Elemental Analysis

FTIR Spectrospcopy Services

Particle Size & Moisture Analysis

Tensile/Shear Mechanical Testing

Taber Abrasion Testing

SKELETAL DENSITY/Gas PycnometRY

Tailored Solutions for Enhanced Bioceramic Implant Outcomes

Many of Himed's most enduring innovations have stemmed from client inquiries. The BCoE extends beyond prototyping and analysis, focusing on optimizing bioceramic materials to achieve desired clinical outcomes. Himed's engineering team works closely with clients to understand their goals and challenges, iterating on designs and material compositions to achieve their intended results.

The BCoE’s optimization process ensures that customers discover what is feasible with their designs and feel confident in the repeatability and scalability of the solutions. Using Lithoz's advanced 3D-printing technology, the BCoE refines and perfects bioceramic material outputs, paving the way for successful commercialization.

Customizing 3D-printable bioink materials for various medical implants is a core component of the strategic partnership between Himed and Lithoz. The next generation of complex, bioresorbable, 3D-printed forms begins with the material testing and optimization that Himed performs daily at the Bioceramics Center of Excellence™.

Ready to discover what is possible with 3D-printed bioceramic materials?

Contact our team to explore how the Bioceramics Center of Excellence™ can support your R&D efforts.